Description:

Description:

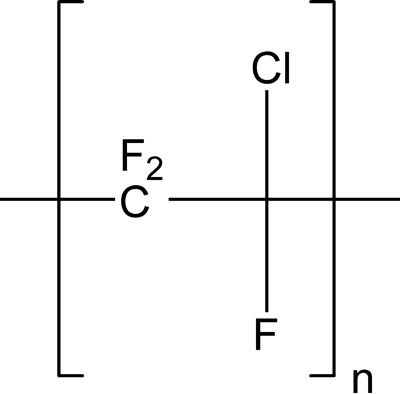

PCTFE is made from chlorotrifluoroethylene by suspension-polymerization or by emulsion-polymerization with a redox-indicator or a peroxide as starting reagent. PCTFE is a semi-crystalline thermoplastic. This material can be process by extrusion or injection moulding in temperature range of 280-350°C. (however at 280°C decomposition of the material begins) The properties of PCTFE are similar to that of PTFE, however PCTFE is harder and less durable compared with PTFE. PCTFE offers a unique combination between physical and chemical properties (not flammable, chemical resistant, excellent electrical properties) which can not be found in any other fluoropolymer. PCTFE is applicable in a wide temperature range (-240°C – 204°C).

Usage:

- Sealing- and slip elements in the chemical apparatus engineering

- laboratory apparatus

- fittings

- tubes

- gauge-glass

- as coating-material for vessels

- for the production of plates, foils and clips

- as envelope for filaments and cables

- foil-material for waterproof packaging of high-grade goods

- as component in low-temperature coolers (low temperature usage)

- for gaskets (o-rings, v-rings, special-gaskets for superchargers and pumps)

- as film for food- or pharmaceutical packaging or electro-luminescence displays

- insulation-material for cables

- valve-production

Formula:

Category:

Thermoplastic