Description:

Description:

Universal testing method applicable to nearly all gases for determining gas transmission rate through flat plastic materials like films, sheetings, laminates, co-extruded or coated materials under a differential pressure.

Result Unit:

- GTR (gas transmission rate) mol/ m2*s*Pa

- usally: cm3 (STP)/ m2 * 24 h STP according DIN 1343: the volume of the gas at 273.15 K (0°C) and 101325 Pa (1 atm)

- normalised to thickness:

- P(permeability) mol*m/m2*s*Pa

- usally: cm3*mm/m2*24 h* at

(Related) Standards:

ISO 15105

Test method:

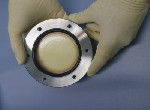

The test sample is mounted in a permeation cell so as to form the barrier between two chambers. Both chambers are evacuated. Afterwards, one chamber is filled with the testing gas.

In the other chamber, the pressure increases because of the transmission through the specimen. The permeation rate is calculated than based on the pressure increase.

Detection limit:

0.01 cm3/m2*day

The detection limit also depends on the nature and thickness of the specimen.

The method is recommended for permeation values > 0.1 cm3/m2*day, because at lower rates the measurement times become very long and costs for the measurement rise. At very low permeation rates, measurement with increased partial pressure difference are recommended to shorten measurement times.

Required specimen:

For testing please send us a sample of the approximate size of a sheet of paper (DIN A4, 210*297 mm).

Scope of the standard: 10 – 150 mm active diameter of the samples.

The specimens shall be uniform in thickness, representative for the material and free of pinholes and folds. On request we measure your sample thickness according to ISO 4593.

We recommend the measurement of three independent samples per test. Our standard is to measure samples of 20 µm – 3 mm, others on request.

Required sample dimension: we perform the preparation of the samples for you.

For different test gases and type of samples we use different sized samples. If you want to conduct the cutting of the specimens yourself, please contact us for the required dimensions. For sensistive coating test it sometimes makes sense to prepare first the support followed by the coating. Please inform us if your samples tend to crack under applied pressure (of the test gas or the sealings).

Testing medium:

Gases, vapours, solvent above boiling point.

Standard: O2, CH4, N2, Ar, He, H2, Cl2

Our permeation measurement cells are all-purpose because they are resistant to corrosion. Please contact us for special applications.

The testing method is normally limited to substances or mixtures which contain substances of strongly skewing permeation rates.

Test conditions:

Scope of the standard: 23 °C +/- 2°C gas at ambient pressure (partial pressure difference about 1 atm absolute)

Mecadi’s possible testing temperatures:

- standard -50 °C up to +150 °C,

- Other temperatures on request (-190°C up to 600 °C possible, requires set-up time)

Mecadi’s possible testing pressures:

- Standard: up to 100 bar, others on request.

Please contact us for information on special effects and requirements for the samples at high pressures.

Also possible are temperature profiles (nonisothermic measurements) for determining the gas transistion temperatures and the influence of media and pressure to polymer properties.

Based on this method Mecadi offers further examination to determine gas solubilities (sorption and desorption), diffusion coefficients and the measurement of break through times through barriers.

Furthermore interactions between media and polymer can be investigated. So the predictions according resitance, physical and chemical reactions under process conditions can help in the selection process of materials.

You find this article here as a PDF. We also do the test sample manufacture for you.